About us

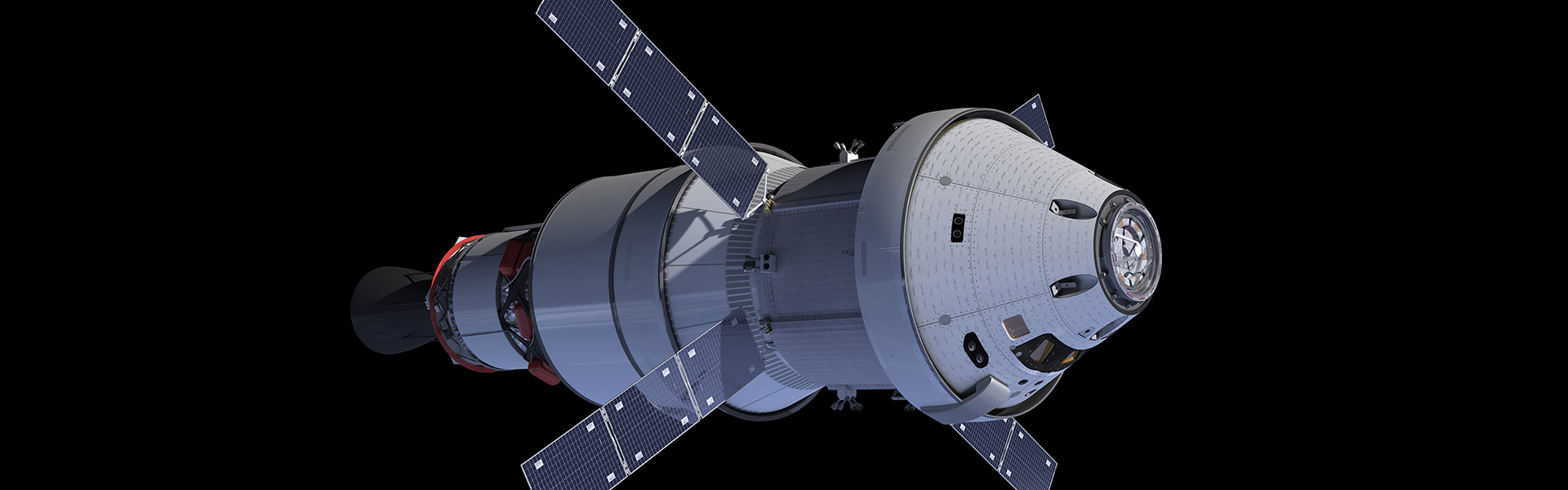

For over 30 years Fomap has provided a high quality service in the field of precision mechanics, specializing in prototypes and small series production.

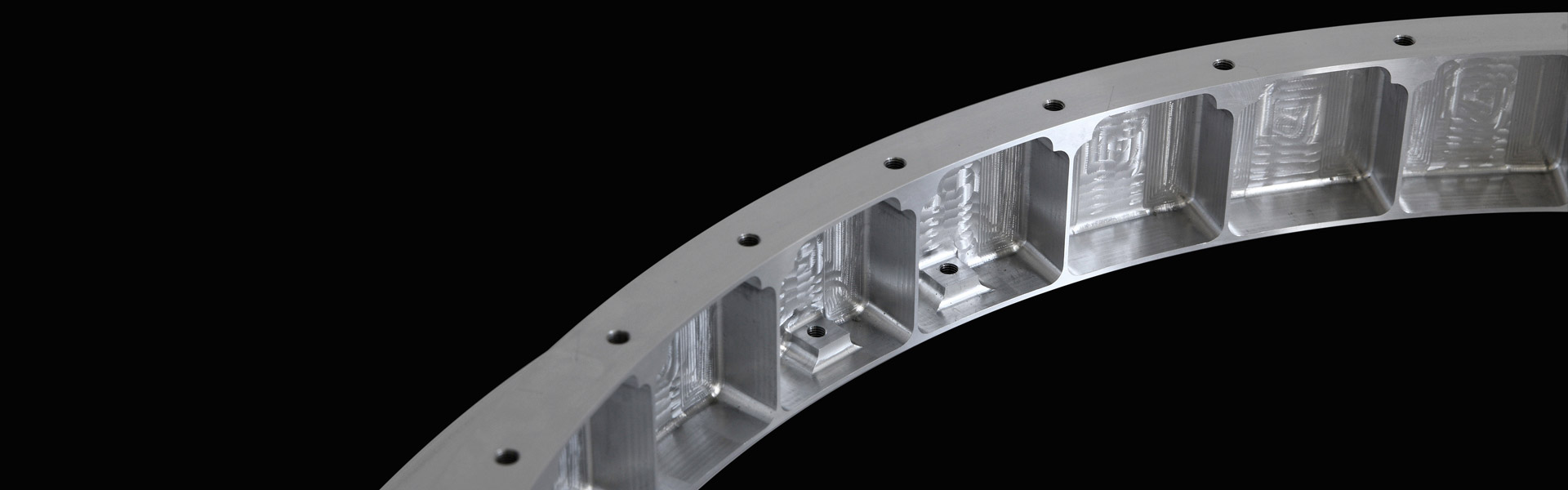

Thanks to highly specialized operators, Fomap is able to offer quality services, ranging from mechanical machining to casting, metal carpentry and forged pieces, to a complete service starting with the provision of materials, machining, special processes, assembly, other intermediate services until final testing, particularly in the realization of those products which require two-place tolerance, thanks to a sophisticated machinery inventory and a wide range of measuring instruments.

We have all the experience and expertise necessary for the realization of finished and functioning parts and the final testing phase. Flexibility, competitiveness and efficiency along with the reduction of lead time are the fundamental characteristics of our stream lined production.

Milling, boring and turning

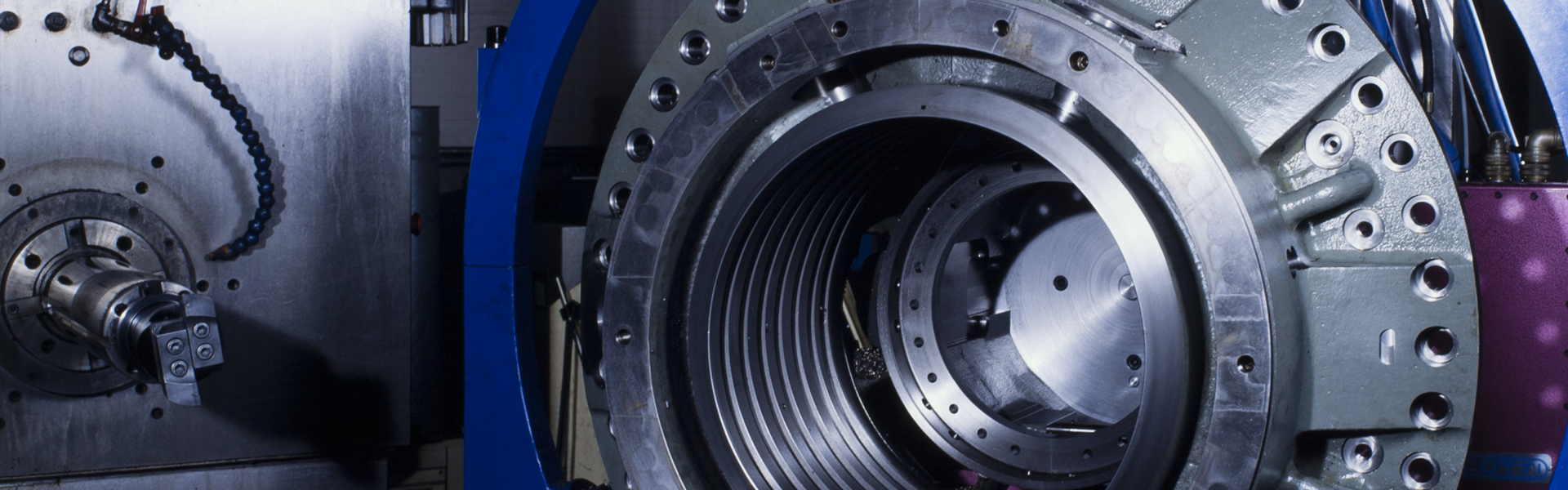

The main services which we provide in this sector of are milling, boring and vertical turning.

In terms of milling and boring, Fomap can work with maximum dimensions of 18000 x 3500 mm with the aid of a rototranslating table, universal heads Gerardi heads and d’Andrea heads.

Vertical turning can reach a maximum diameter of 3200 x 3000 mm (height) .

Our specialized and high quality equipment also enables us to handle fusions, metal carpentry and forgings up to a maximum of 40T (40,000kg). To complete the technological cycle, Fomap also develops special processes such as welding (TIG, MIG, MAG ) to ASME specifications, electron beam welding (EBW), surface treatment, non-destructive testing, powder deposition welding ( HVOF coating).

Single unit, prototypes and limited production series

Single pieces, prototypes and small series production.

We offer a service of realizing prototypes and small series of high quality thanks to our specialized operators, solid and technologically advanced machinery and state of the art measuring equipment and tools.

Study, design, finding the best solution for the processing of single pieces and small series, but above all reducing the margin of error to zero: we pay close attention to costs and lead times (or deadlines), thus offering our customers a maximum flexibility.